#576 Spray Booth

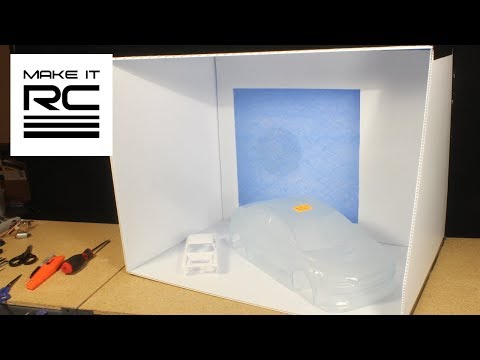

Building a $10 spray booth for light airbrush spray painting and soldering.

Here’s a quick demo..

Notes

Quality commercial spray booths can be quite expensive (starting from over $125 locally), but they can be value for money, offering strong airflow and quality construction.

But perhaps a more modest solution will suit my more modest needs - basically for fume extraction for soldering and light, small scale airbrush spray painting.

Inspiration

There are many examples of DIY spray booth construction just an internet search away. Here are a few I checked out.

DIY Airbrush Spray Booth Setup & Build (frostedsnow)

I Finally Built Myself an Airbrush Spray Booth!

Airbrush Spray Booth Build

Make a foldable painting booth!

Construction

OK, I’m going super cheap. My only new purchase was the fan (~$3) and filter ($2), the rest scavenged from parts bins and the trash:

- an old cardboard box 20cm (H) x 27cm (W) x 43cm (L)

- 120x25mm 12V DC brushless fan (1800rpm, probably only about 60cfm)

- Daiso 20cm x 20cm ventilation port adhesive filter

- 36 LEDs - cool white 12V LED strip

- 18 LEDs - warm white 12V LED strip

- 12V 1A+ power adapter

- 2 panel-mount SPST switches

- 5.5mm x 2.1mm panel-mount DC jack

- some wire

- some masking tape

- a small plastic project case for the junction box

Testing the components:

- the LEDs draw about 260mA at 12V. The mix of cool and warm white produces a very clear and comfortable light.

- the fan draws about 290mA at 12V. It is very quiet - acoustically and electrically. No voltage spikes at startup or stop, so no need for additional smoothing and suppression components.

Thus a very simple circuit:

Inside the junction box:

Rear view with fan and junction box attached:

Exhaust/Ventilation Considerations

There are three main factors to consider:

- airflow (volume/time)

- filtering requirements

- where and how to vent the exhaust

Actual requirements will depend on the the toxicity and volume of aerosols being released.

Since I am only dealing with low volumes of solder flux fumes and generally non-toxic water-based acrylic paint, I’m keeping this simple and probably under-engineered:

- airflow: I’ve seen 200cfm+ being mentioned as ideal for airbrush work. For now I’m using a very quiet 120x25mm DC brushless fan that only moves about 60cfm)

- filtering: since I’m not dealing with high volumes of toxic material, my main concern is suppressing dust and paint so I’m using a cheap household grade filter

- vent: I don’t live in a house or climate that allows easy direct venting to the outside, so this is strictly for indoor use and only to move fumes from the immediate vicinity

If I needed to upgrade this to deal with larger volumes of fumes or more toxic materials, I would probably (a) find another place to do this other than in the home and/or (b) replace the exhaust system with an industrial inline fan with ducting to extract and vent to the outdoors.

Some typical DC brushless fan specs:

| size | Speed | Air Flow | Noise (dBa) |

|---|---|---|---|

| 40x10mm | 5000RPM | 5CFM , 0.14m3/min | 33dBa |

| 50x10mm | 4500RPM | 7CFM , 0.23m3/min | 32dBa |

| 60x25mm | 3600RPM | 22CFM , 0.62m3/min | 31dBa |

| 80x25mm | 3000RPM | 43CFM , 1.22m3/min | 31dBa |

| 120x25mm | 2000RPM | 70CFM , 2.00m3/min | 33dBa |